Precision in Every Measure

Elevate Your Experience with Our Weighing and Packaging Solutions

Search For Products

Product Categories

Checkweigher with Metal Detector

CW 1.2K is a highly accurate checkweigher meant for accurate weight measurements. This machine has a durable SS304 stainless steel structure with the highest-grade electronic interface to accurately measure weights at a high speed. It can be used for checkweighing in food, agro, pharmaceutical, textile, chemical and other industries.

User-friendly electronic interface

- 10-inch colour TFT touch screen for better control

- Automatic zero tracking and weighing compensation

- Measuring time automatic adjustment

Product adjustment flexibility

- Case or bag weighing up to 1200g

- Integration in any production line made easier

Weighing measurement features

- Can store up to 1 million weight value data for production statistics

- Printable data ready to import via a USB port

- Belt speed can be varied as per need

Design functionality

- Metal detection and weight-check features combined

- Weight measurement for quality control of packaged and unpackaged items

- High-quality electronic parts

- Strong and durable conveyor components

- Statistical data for evaluating production efficiency

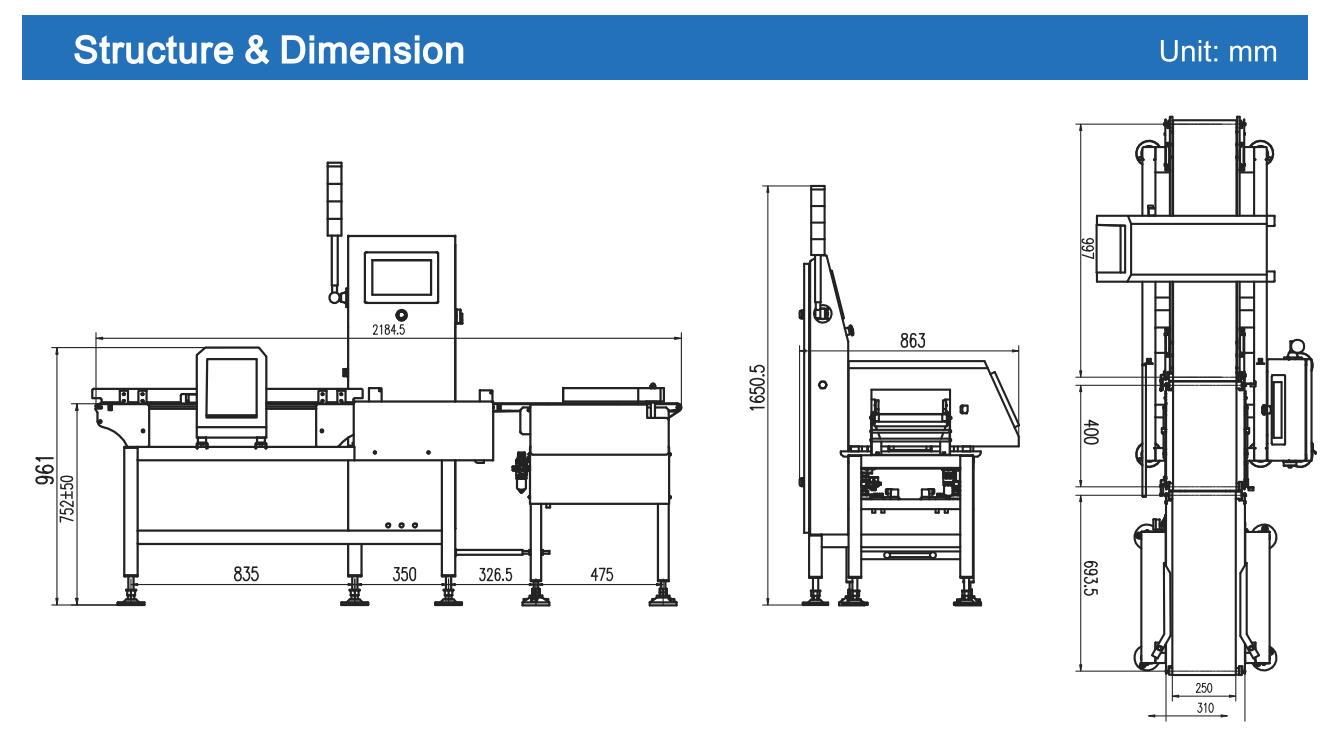

| Model | CW-1.2K | |

| Power | AC 220V±10%, 50/60Hz, 400W | |

| Weighing Range | 100~1200g | |

| Weighing Accuracy | ±0.7g | |

| Weighing Speed | ≤100 pcs/min | |

| Belt Speed | 5~40 m/min | |

| Belt Size | 400mm*250mm | |

| Belt Material | PU White | |

| Structure Material | 304 Stainless Steel | |

| Rejector | Optional: swing arm, push type, air blow | |

| Metal Detection Sensitivity" | Fe ≥ 0.8mm, Sus304 > $2.0mm, Non-Fe ≥ $1.5mm | |

| Metal Detector Wide | 250mm | |

| Metal Detector Height | Optional: 80mm/100mm/120mm/150mm/200mm | |

| Platform Height | 750±50mm | |

| Working Temperature | 0~40°C | |

| Maximum Humidity | 90% R.H No Condensation | |

| Limit Load | The instantaneous load shall not exceed 2.4kg |

Online Checkweigher with Metal Detector

Brochure

Download

Download

FAQ

Clearing Up Your Queries and Providing Informed Solutions

What is a checkweigher with metal detector?

It's a Combo system for dynamic weighing and metal detection at a same time in production lines.

How does this work?

Products pass through, weight is measured, and metal is detected(if any) simultaneously.

In which industries can this be used?

Dairy,Food, pharmaceuticals, and any industry needing strict quality control.

Does it also store data?

Yes

How many pieces can it check in a minute?

90

Why is it important to have both weight checking and metal detection in one machine?

Ensures compliance and safety, meeting standards and preserving brand integrity.

How accurate is this

Plus minus 1 gram in 1200gm combo model. Highly accurate

Is this easy to integrate into existing production line?

Yes, designed for seamless integration with flexible mounting and user-friendly interfaces.

Can this be integrated with other quality control systems or data management softwares?

They minimize false alarms while maintaining high sensitivity to genuine deviations.

RELATED PRODUCTS

Prompt Is a leading manufacturer of electronic weighing scales

CASE STUDY

Real-World Success Stories

An Automatic Weight Checking Solution for Dairy Industry.

Check Weighing Machine – Case Study

Prompt Equipments is serving people for over four decades now and wishes to carry this service as a legacy in the years to come.

Read More

Delivering smart checkweigher solutions for improved packaging of electrical products

Online checkweigher – Case Study

Prompt Equipments is serving people for over four decades now and wishes to carry this service as a legacy in the years to come. We provide innovative solutions to some of the biggest manufacturers in India.

Read More